阿特拉斯·科普柯是一家全球领先的建筑设备制造商,其将携一系列创新的产品亮相于4月16-21日在巴黎维勒班展览中心举行的Intermat 2012。

在Intermat展会期间,阿特拉斯·科普柯欢迎观众亲临其展位,感受其展示的节能产品和可持续的生产力。这次的展品包括从空压机和钻井设备到破碎设备和压路机的一系列创新的节能产品,旨在满足用户在今后许多年中提高生产力,降低运行成本的需求。

节能产品

SmartROC T35/T40露天钻机

点击此处查看全部新闻图片

今年年初,阿特拉斯·科普柯在拉斯维加斯的CONEXPO-CON/AGG展览会上推出了新型SmartROC T35/T40露天钻机,现已占据了大型节能省钱机械的领先地位。由于采用全新的控制系统平台,能够确保为每项功能精确地提供恰如其分的能量。正是凭借有效地利用每一千瓦能量,极大地降低了的燃料消耗——根据岩石条件,最高可节省燃油消耗达50%——同时也将碳排放量降到最低。为此,综合钻机的优异性能,SmartROC T35/T40已获得5个国家许多承包商最高评价等级。新增的亮点还有全新改进的消音罩以及无线遥控装置。

单钢轮振动压路机

点击此处查看全部新闻图片

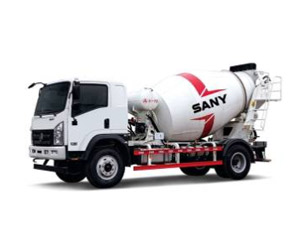

阿特拉斯·科普柯第5代单钢轮振动压路机,满足持续、高效的强劲动力需求,更加注重环保和极端适用性。CA5000,CA6000和CA6500单钢轮压路机是首批配置了可使用普通柴油和生物柴油的发动机。独特设计的“最佳点”节油系统降低了燃油消耗和二氧化碳排放,发动机后置安装和易于打开的发动机罩满足了维修保养的便利性。

QAC1250发电机组

点击此处查看全部新闻图片

QAC1250是阿特拉斯·科普柯推出的首台1MW现场型发电机组,具有一贯的高效节能的特点。QAC1250发电机组结构设计紧凑,可靠性高,能提供高达1450kVA/1150kW的主用动力。QAC1250专门针对现场型电力需求而设计,能承受极端恶劣的天气条件的考验,同时由变频电机驱动的冷却风扇以确保机组在全负荷范围内达到最佳的燃料消耗率。它是偏远的施工工地的理想选择。此外,该发电机组噪声极低(67dB(A)),在噪声要求严格的敏感地区是完美选择。QAC1250发电机组与其它QAC系列机组一样,集成在标准的20“集装箱内,运输和安装简单、迅捷而安全。

CC900E双钢轮压路机

点击此处查看全部新闻图片

CC900E双钢轮压路机是阿特拉斯·科普柯公司的路面压实专家——戴纳派克品牌推出的最新零排放概念产品,完全的电驱动,实现零排放,是目前全球首款电动沥青压路机。

首次亮相

移动式破碎机

点击此处查看全部新闻图片

对Intermat观众而言,这是阿特拉斯·科普柯Powercrusher系列移动式破碎机的首次亮相,清晰地向公众展现了阿特拉斯·科普柯在破碎机械技术方面的专业水准。具有代表性的Powercrusher PC 4,是一款坚固耐用的鄂式破碎机,每小时产量达到300吨。所有的Powercrusher破碎机都是阿特拉斯·科普柯自行开发生产的高质量产品,它们与阿特拉斯·科普柯钻机可配套使用,提供钻孔、破碎及筛分的全面解决方案。

Weda水泵

点击此处查看全部新闻图片

Intermat上展出的另一款阿特拉斯·科普柯家族的新成员是Weda水泵。Weda专为采矿、采石、建筑、租赁和国防等工业领域而设计,以其优良性能、高可靠性和操作简便的特性而享誉业内。

打破壁垒

HB4100重型液压破碎锤

点击此处查看全部新闻图片

阿特拉斯·科普柯成功推出全新的HB4100重型液压破碎锤。该款破碎锤虽比其前款轻了130公斤,但性能更好,效率更高。承受极端条件的耐久性的提高和适应能力的增强,这两者都有助于降低总拥有成本。此外,4100公斤的工作重量可以匹配更小的载机(40-70吨),从而减少初投资。

实现可持续的生产力

阿特拉斯·科普柯还将展示许多能提高效率,实现可持续生产力的创新设计。

SmartROC T35/T40台车升级消音装置

点击此处查看全部新闻图片

例如,阿特拉斯·科普柯为SmartROC T35/T40台车升级消音装置就属于一种智能性的尝试。这种装置能够将凿岩噪音再减少2 dB(A),声功率总计下降12 dB(A)。另外一个便是无线遥控装置。它的重量不到3kg,开阔地形作用范围50m,每节电池可使用12小时。只要简单地将驾驶室中的模式开关拨到“remote”,便可激活这个功能。阿特拉斯·科普柯设计生产的产品,可以与全球范围内使用的所有SmartROC钻机兼容。

EDGE钻孔监测系统

点击此处查看全部新闻图片

另一个例证是用于潜孔钻机的EDGE钻孔监测系统,一套能告诉钻工钻孔时潜孔锤和钻头在孔底的工作状况的设备。这些信息在屏幕上实时显示,能够让钻工优化最佳钻孔速度、保持良好的冲渣条件并减少钻孔过深。因此,避免了钻具断裂和代价高昂的误工。EDGE可以安装在使用赛柯洛克(SECOROC)潜孔锤的任何型号的深孔钻机上。

T-WiZ系列钻具

点击此处查看全部新闻图片

当说到易耗品时,钻孔的持久性是始终不变的关注重点。阿特拉斯·科普柯也是一样,最近又进一步推出了T-WiZ系列钻具,它具有市场上最坚韧的T型螺纹系统。T-WiZ 快速钻杆和T-WiZ钎尾的配合使用可以延长30%以上的使用寿命,使得钻杆更换次数更少,每班生产率更高。

在地下施工领域,阿特拉斯·科普柯的领先技术早已得到公认。在Intermat展会上,Boomer E2 C凿岩台车将再次向观众展示其卓越的性能。这种双臂液压隧道开凿和采矿机械,配有阿特拉斯·科普柯先进的钻机控制系统,可以装配COP 1838ME、COP 2238和COP 3038凿岩机。配合重型BUT 45钻臂和自动换杆系统,这种台车是全世界地下施工承包商提高生产力的首选。

总而言之,阿特拉斯·科普柯(5B馆,F015/F027)将是本次Intermat展会上最值得参观的展位之一——可能为您降低成本,增加收益。

关注创新奖项

五款正在参与Intermat创新奖项评选的阿特拉斯·科普柯产品将在本次展会上展示,它们是:

SmartROC T35/T40露天钻机

QAC 1250移动式发电机组

CA6000 单钢轮振动压路机

CC900E 零排放电动压路机

XAS 27移动式空压机

Atlas Copco focus on energy at Intermat 2012

Atlas Copco,one of the world’s leading manufacturers of construction equipment,is planning to display an impressive line-up of innovative products for the 2012 Intermat show,16-21 April,at the Paris-Nord Villepinte center.

There will be no mistaking Atlas Copco’s quest for energy-saving equipment and sustainable productivity when the company welcomes visitors to its booth at Intermat 2012. Its extensive and innovative product range – covering everything from air compressors and drilling equipment to equipment for demolition,crushing,road paving and soil compaction – takes energy efficiency to new heights. The aim is to give contractors the means to meet tougher demands for high productivity at low operating cost for many years to come.

MONEY SAVER

Launched at the CONEXPO-CON/AGG show in Las Vegas earlier this year,the new SmartROC T35/T40 surface drill rig has already created a frontline position for itself as a big money saver. Based on a completely new control system platform,it ensures that precisely the right amount of energy is generated for each function. This efficient use of every single kilowatt results in a drastic reduction in fuel consumption – up to 50% depending on rock conditions – and also reduces carbon emissions to a minimum. For this reason,coupled with the rig’s superior performance,the SmartROC T35/T40 has received top ratings from contractors in five countries. Added benefits include a new and improved silencer hood and radio remote control.

Continuing the quest for energy efficiency,Atlas Copco’s fifth generation of CA single drum vibratory rollers breaks new ground for efficiency,environment friendliness and extreme serviceability. The CA5000,CA6000 and CA6500 compactors are the first of their type with cross-mounted engines and run on biodiesel as well as diesel. A “Best Point” fuel-saving system reduces fuel consumption and CO2 emissions to an absolute minimum while the rear-mounted engine and easy-to-open hood allows excellent access for all service and maintenance needs.

Energy efficiency is also a key feature of the QAC 1250 generator,the first 1 MW generating unit from Atlas Copco. This is a compact,highly reliable unit that delivers up to 1450 kVA/1150 kW of prime power. Specially designed to withstand extreme weather conditions it is equipped with an electric,variable speed,motor-driven cooling fan which ensures optimal fuel consumption. Ideal for remote construction sites,the generator is also very quiet-running (67 dB(A) which makes it a perfect choice in sensitive areas. It is also supplied in the same standard size container as previous models which make it easy,fast and safe to transport and install.

The concept asphalt roller CC900E from Atlas Copco’s road paving specialist Dynapac provides a glimpse of the future and is well worth seeing. With its battery driven system it is entirely emission-free and,if available on the market,would be a world first in asphalt compaction.

MAKING THEIR DEBUT

Another first,this time for Intermat visitors,is the appearance of Atlas Copco’s Powercrusher range of mobile crushers,clearly demonstrating Atlas Copco’s expertise in crusher technology. Representing the range will be a Powercrusher PC 4,a highly rugged and durable jaw crusher with a capacity of up to up to 300 tonnes per hour. As all Powercrusher units are high quality products developed and manufactured by Atlas Copco in-house,they are perfectly suited for use together with Atlas Copco drill rigs.

Another newcomer to the Atlas Copco line-up at Intermat is the Weda pump. Designed for the mining,quarrying,construction,rental and defence industry sectors,WEDA pumps are renowned for performance,reliability and ease of use within the most demanding applications.

BREAKING BARRIERS

When it comes to heavy duty hydraulic breakers,Atlas Copco has excelled once again with the launch of its new HB4100. This breaker is 130kg lighter than its predecessor but gives a better performance and higher efficiency. Durability has been improved to withstand extreme conditions and serviceability has been enhanced,both of which contribute to reducing the total cost of ownership. Furthermore,the service weight of 4100 kg enables smaller carriers (40-70 tonnes) to be used,thereby reducing the initial investment.

TOWARDS SUSTAINABLE PRODUCTIVITY

The Atlas Copco display will also include a large number of improvements designed to not only make construction operations more productive but also more sustainable.

For example,Atlas Copco’s updated silence kit for the SmartROC T35/T40 drill rig is an intelligent step forward. The kit reduces drilling noise by a further 2 dB(A) to a total sound power reduction of 12 dB(A). Another example is the Radi Remote control unit. Weighing less than 3 kg,has a range of up to 50 m in open terrain and each battery lasts up to 12 hours. it is easily activated by simply switching the mode switch in the cabin to “remote”. designed and manufactured by Atlas Copco in-house,it is compatible with all SmartROC drill rigs wherever in the world they are used

Another example is the EDGE drill monitor system for down-the-hole drilling,a system that shows the driller what is happening with the hammer and the bit at the bottom of the hole during drilling. The information is displayed on a screen in real time,allowing the driller to optimize the penetration rate,maintain good flushing and reduce the chance of over-extending the tools,thereby avoiding breakage and costly delays. EDGE can be fitted to all types of deep hole drill rigs that use Secoroc DTH (down-the-hole) hammers.

Durability in drilling is a constant concern and especially when it comes to consumables. Here,too,Atlas Copco has pushed the envelope further with the introduction of T-WhiZ,said to be the toughest T-thread system on the market. The combination of T-WhiZ Speedrods and T-WhiZ shank adaptors increases service life by up to 30 percent resulting in fewer rod changes and more productivity per shift.

In the area of underground construction,Atlas Copco’s know-how is well documented and at Intermat the company’s expertise will be represented by a Boomer E2 C drill rig. This two-boom,hydraulic tunnelling and mining rig features Atlas Copco’s advanced Rig Control System and can be equipped with COP 1838ME,COP 2238 as well as COP 3038 rock drills. Together with its heavy duty BUT 45 booms and automatic rod handling system the rig is a favorite choice providing superior productivity for underground contractors around the world.

All in all,the Atlas Copco display at booth (Hall 5B,stand F015 / FO27) promises to be one of the most informative and worthwhile exhibits at Intermat – and for many,a visit that may well lead to lower costs and increased revenues.

WATCH OUT FOR INNOVATION AWARDS

Five products from the Atlas Copco range are currently being considered for the coveted Intermat Innovation Awards which will be presented during the show. These are:

- SmartROC T35/T40 surface drill rig

- QAC 1250 portable generator

- CA 6000 single drum vibratory roller

- CC900E emission free roller

- XAS 27 compressor

热门推荐