HENGWANG·GROUP

Drilling rig

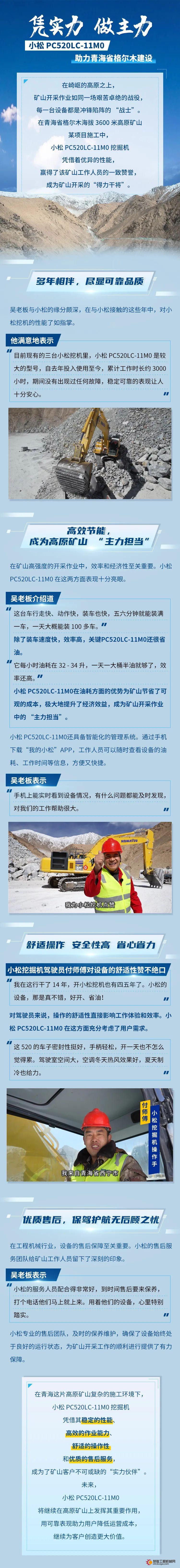

在工程和采矿行业中,

钻机是完成任务的重要设备。

为了保证其高效、稳定地运行,

定期的维护工作不可或缺。

Through the continuous execution of these key steps, we can not only ensure the stability and high efficiency of the drilling rig but also significantly reduce long-term operational costs. Remember, good maintenance habits are the foundation for ensuring the long-term stable operation of the equipment. Let's start today, together for the "health" and "longevity" of the drilling rig.

01

KEEP CLEAN

保持基础清洁

DRILLING RIG

钻机的日常清洁是维护工作的基础,也是最重要的一步。每次使用结束后,用压缩空气或清水彻底清理机体,尤其是散热器和空气滤网。这不仅可以防止因过热导致的性能下降,也能避免粉尘和泥浆积累引发的故障。

Daily cleaning of the drilling rig is the foundation of maintenance work and the most important step. After each use, thoroughly clean the machine with compressed air or clean water, especially the radiator and air filter. This can prevent performance degradation due to overheating, as well as avoid faults caused by the accumulation of dust and mud.

02

REGULAR INSPECTION

定期检查与紧固

每周至少进行一次的细致检查,可以帮助我们发现并及时处理磨损或损坏的迹象。特别是钻杆和钻头这类高磨损部件,需要特别注意。同时,不要忘记检查所有螺栓和螺母,确保没有因振动而松动,这是保证设备稳定性的关键。

Conducting a detailed inspection at least once a week can help us detect and address signs of wear or damage in a timely manner. This is particularly important for high-wear components such as drill rods and drill bits. At the same time, do not forget to check all bolts and nuts to ensure they have not loosened due to vibration, which is key to ensuring the stability of the equipment.

03

REGULAR LUBRICATION

定期润滑

DRILLING RIG

定期对所有需要的部位进行润滑。这不仅可以减少部件间的摩擦,降低磨损,还能防止锈蚀,保护机械部件。适当的润滑是保持钻机顺畅运行的秘诀之一。

Regularly lubricate all necessary parts. This can not only reduce friction between components, decreasing wear, but also prevent rust, protecting the mechanical parts. Proper lubrication is one of the secrets to keeping the drilling rig running smoothly.

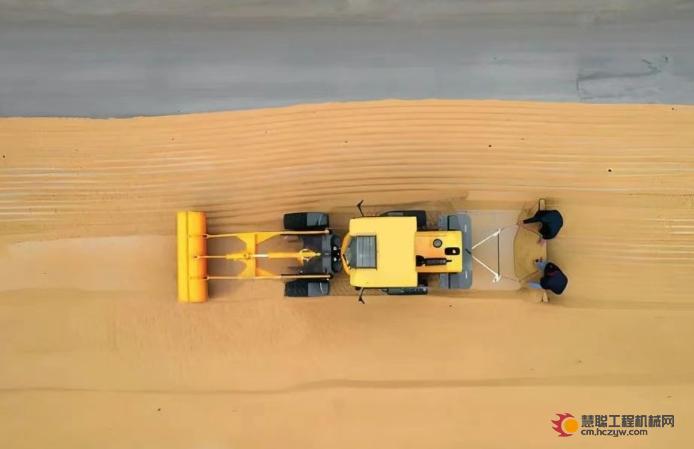

04

REPLACE WEAR PARTS

及时更换易损件

钻头和滤网等易损件的定期更换是维护工作中不可忽视的部分。根据使用频率和工作条件,制定合理的更换周期,可以有效预防故障的发生,保证作业的连续性和高效性。

Regular replacement of wear-prone parts like drill bits and filters is an indispensable part of maintenance work. Establishing a reasonable replacement schedule based on usage frequency and working conditions can effectively prevent failures, ensuring the continuity and efficiency of operations.

05

SYSTEM INSPECTION

系统检查

定期对电气和液压系统进行检查,确保所有电缆和连接器没有磨损或损坏,液压油位和油质处于良好状态。这样可以避免突发的系统故障,确保钻机的安全稳定运行。

Regularly inspect the electrical and hydraulic systems to ensure that all cables and connectors are free from wear or damage, and that the hydraulic oil level and quality are in good condition. This can prevent sudden system failures and ensure the safe and stable operation of the drilling rig.

通过这些关键步骤的持续执行,我们不仅能保证钻机的稳定和高效运行,还能显著降低长期的运营成本。记住,良好的维护习惯是确保设备长期稳定运行的基础,让我们从今天开始,共同为钻机的“健康”和“长寿”

By continuously carrying out these key steps, we can not only ensure the stable and efficient operation of the drilling rig but also significantly reduce long-term operational costs. Remember, good maintenance habits are the foundation for ensuring the long-term stable operation of the equipment. Let's start today, together for the "health" and "longevity" of the drilling rig.

-END-

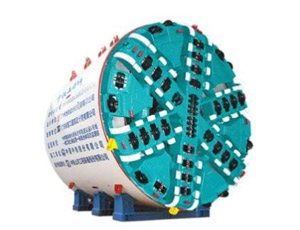

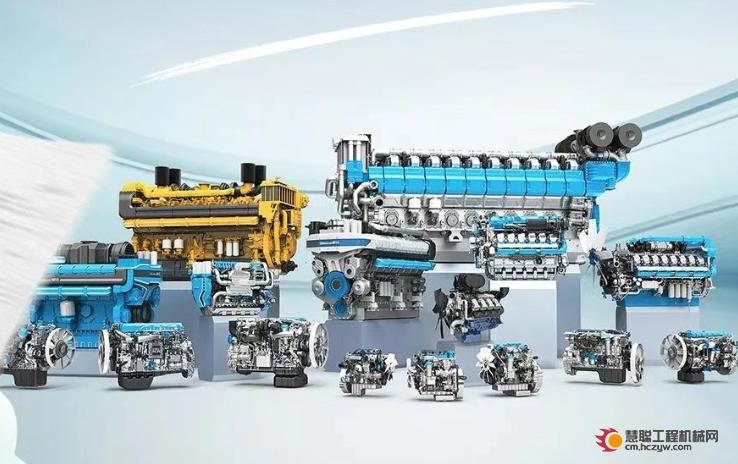

山东恒旺集团以“让最广泛的用户享受最高性价比的产品及服务”为使命,不断推出新产品,提供全方位服务。主营产品类目齐全,包括挖掘机、推土机、钻机、打桩机、压路机、履带运输车等20大系列180余种。产品通过ISO、欧盟CE、德国TUV、法国BV等十余项安全检测认证。

Shandong Hengwang Group, with the mission of "providing the widest range of users with the highest cost-effective products and services," continuously introduces new products and offers comprehensive services. Our main product categories are comprehensive, including excavators, bulldozers, drilling rigs, piling machines, road rollers, tracked transport vehicles, and more, totaling over 20 series and 180 varieties. Our products have obtained more than ten safety testing certifications, including ISO, EU CE, Germany TUV, France BV, and others.

干工程、选恒旺、事业兴旺!

热门推荐